Servizi

DESIGN AND INDUSTRIALIZATION

Mce places a complete design service at customer’s disposal with the intention of designing products that are easy to be realized.

The analysis of problems that can come out during the production starts from the design stage in order to optimize the production cycle.

MATERIAL PURCHAISING

Mce has an efficient purchase department that carefully supplies the materials necessary for the production.

The research of the best suppliers assures high competitiveness of prices and supply times.

We buy components according to customer requirements.

STOREHOUSE MANAGEMENT

MCE has automated vertical warehouses, which optimize loading/unloading operations.

The chip counter machine, through RX and AI technology, allows the automatic counting of components in a few seconds, ensuring correct management of the quantities in the warehouse.

This management is used both for components owned by MCE and for materials received on a subcontract basis from customers.

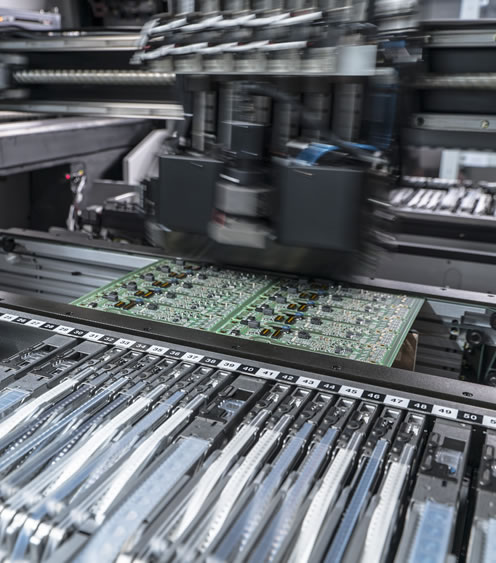

ASSEMBLING OF SMD COMPONENTS

The Hi-Tech department dedicated to SMD assembly covers an area of 600 sq. with air conditioning.

MD production is realized using 8 placing machines that guarantee high daily production, flexibility and production differentiation.

Mce has also a new machine to rework the BGA (disassembly and reassembly). We carry out thermal profiling towards the daily certification of the reflow soldering.

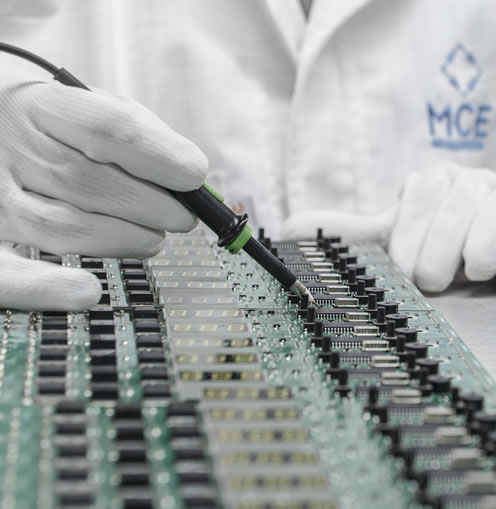

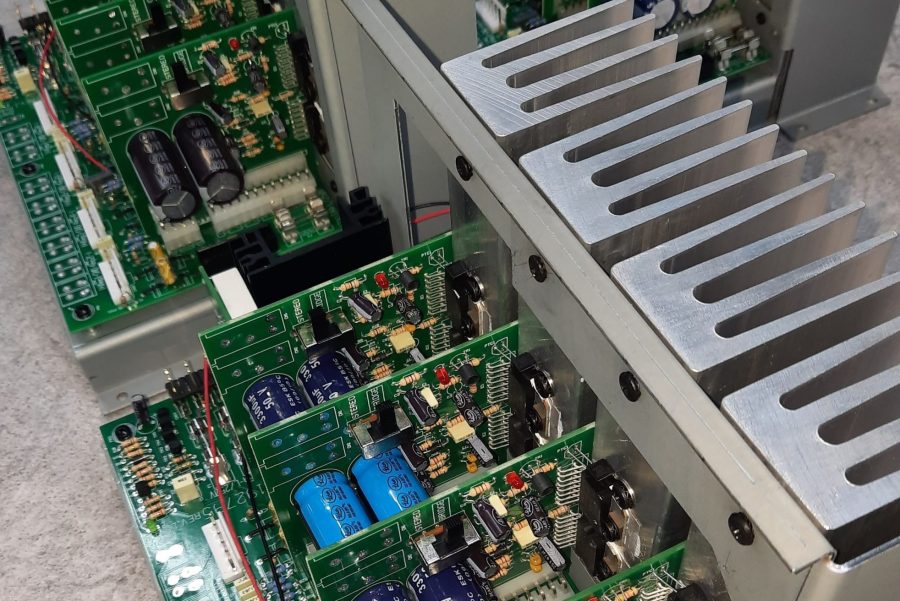

ASSEMBLING OF PTH COMPONENTS

Thanks to our solid know-how and our many

years in the sector, we offer competence and dependability when it comes to assembly and soldering of PTH parts.

PTH components are assembled automatically or manually.

We carry out the welding using a wave soldering or a selective soldering machine depending on the product.

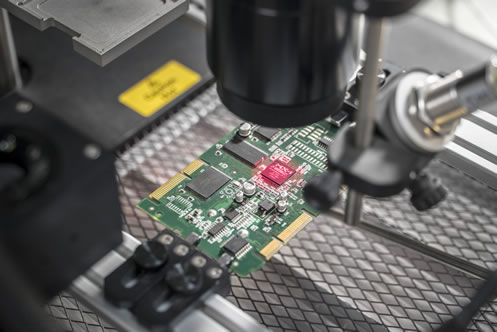

AUTOMATIC OPTICAL INSPECTION AND TEST CERTIFICATE

100% of our electronic cards are subject to an optical test using 2 inspection machines that identify the presence of defects and assembly errors.

Our high quality standard is achieved thanks to the AOI 3D control over 100% of the production.To complete the range of devices for the

inspection of the sheets, we use x-rays, absolutely necessary for the validation of the production process and for service. The boards’ functional test is done with automatic or semiautomatic custom testing tools created by us in collaboration with our clients.

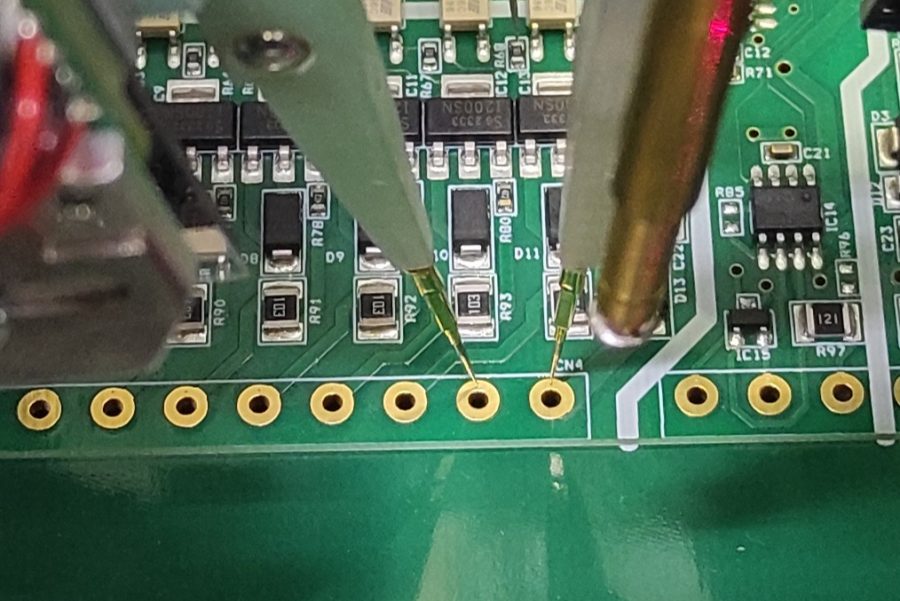

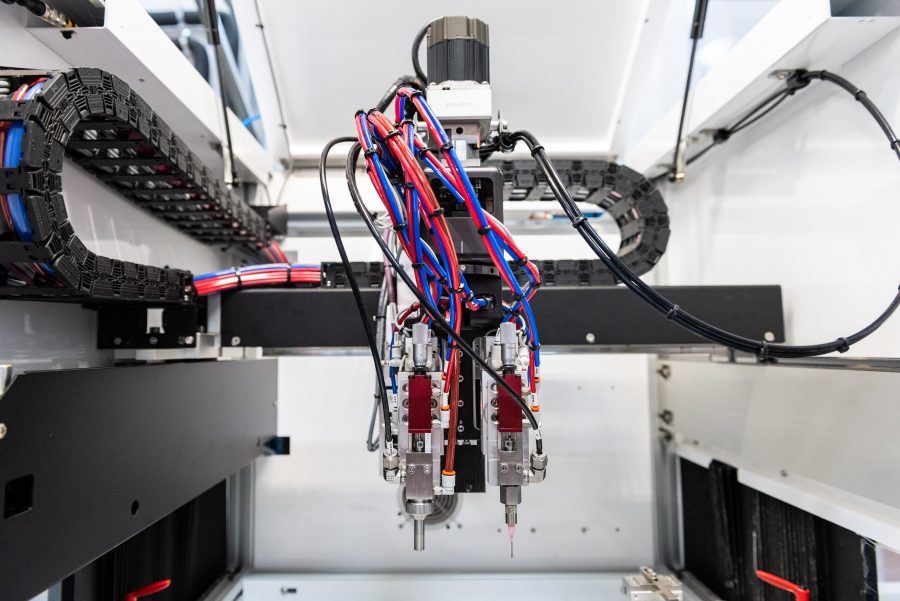

ICT WITH FLOATING PROBES

Upon customer request, in-circuit tests are performed using a flying probe machine.

Testing of electronic boards using flying probes is an advanced technique that allows testing complex circuits without the need for dedicated fixtures.

The system allows checking the values of the components (resistances, capacitances and inductances), continuity and electrical insulation, polarization and operation of semiconductors (diodes, transistors, ICs) and also the operation of digital circuits.

Speed of testing, early detection of defects, and high percentage of defect coverage of an assembled board are the main advantages of this type of test.

BURN IN

Mce disposes of a climatic chamber to simulate the ageing of our electronic equipment. Thermal cycles can be customized within a range of temperature between -40 and 180 °C.

Our company has also another climatic chamber (8 square metres) used to take tests of heating only, at uniform temperature up to 60 °C.

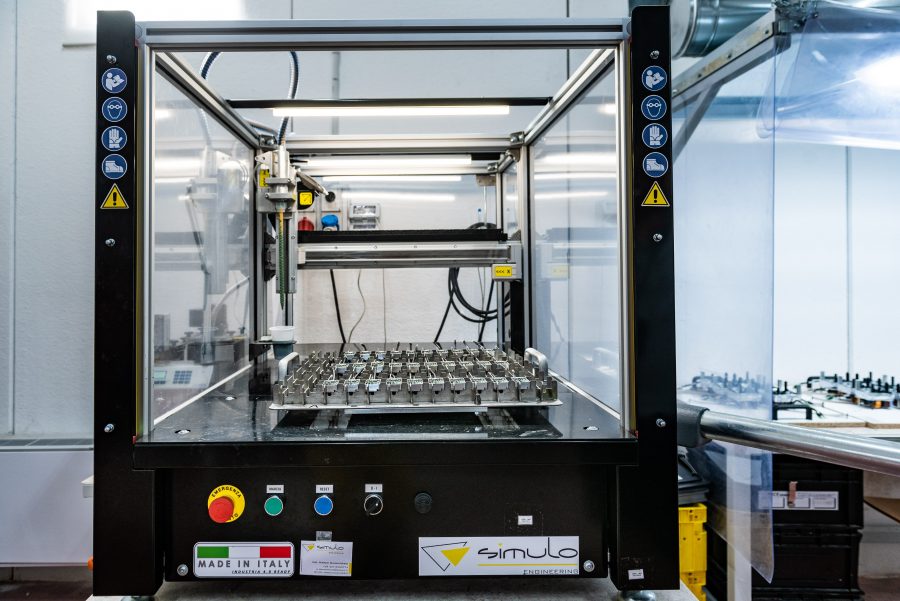

RESINATION

In order to protect the electronic boards from particularly harmful environmental agents, we carry out, at the customer’s request, a coating with two-component resin.

The deposited resin forms a unique body with pcb and components and isolates them from the outside.

The resin is particularly useful for boards subject to vibration.

CONFORMAL COATING

In order to increase the electrical insulation and protect the boards from environmental factors (e.g. humidity, dust, saline environments, corrosion), we perform a conformal coating treatment that consists in dispensing a transparent protective film of protective paint.

MECHANICAL ASSEMBLAGE

Mce has a dedicated mechanical assemblage department used to complete the electronic equipment.

By way of completing of the electronic part, the mechanical work is performed by qualified staff in special areas.

PACKAGING AND CONSIGNMENT

Mce directly delivers its finished products in the neighbouring area; carriers that have an agreement with the firm deliver goods in Italy or in foreign countries.

AFTER-SALE SERVICE

For all articles sold, we offer postpurchase

service, fast and well handled.