Servizi

STORAGE OF SMD COMPONENTS

- Armadio a umidità controllata <5% RH

- Backing 40°C

- Monitoraggio h24 tramite datalogger

- Capacità 1200 l

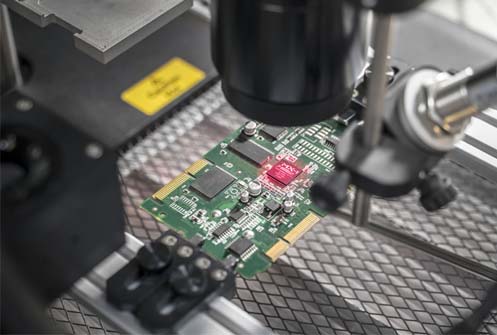

CHIP COUNTER

- RX Technology

- AI-based counting algorithm

- High processing speed

- Counting of 4 rolls simultaneously

- Automatic inventory label printing

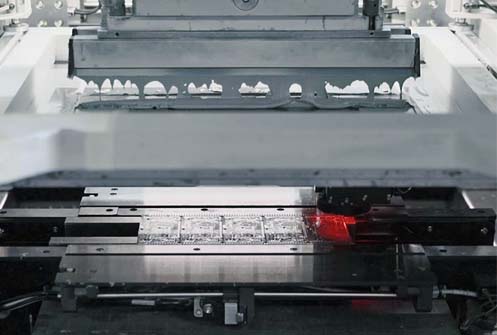

AUTOMATIC SCREEN PRINTING

We utilize sheets with nanotechnology and automatic optical control of the silk-screen production process.

PICK & PLACE

Ours is an up-to-date machinery ensemble. Our pick & place items, efficient and flexible, adapt to every SMD-assembly need.

REFLOW SOLDERING OVEN

We carry out thermal profiling towards the daily certification of the reflow soldering.

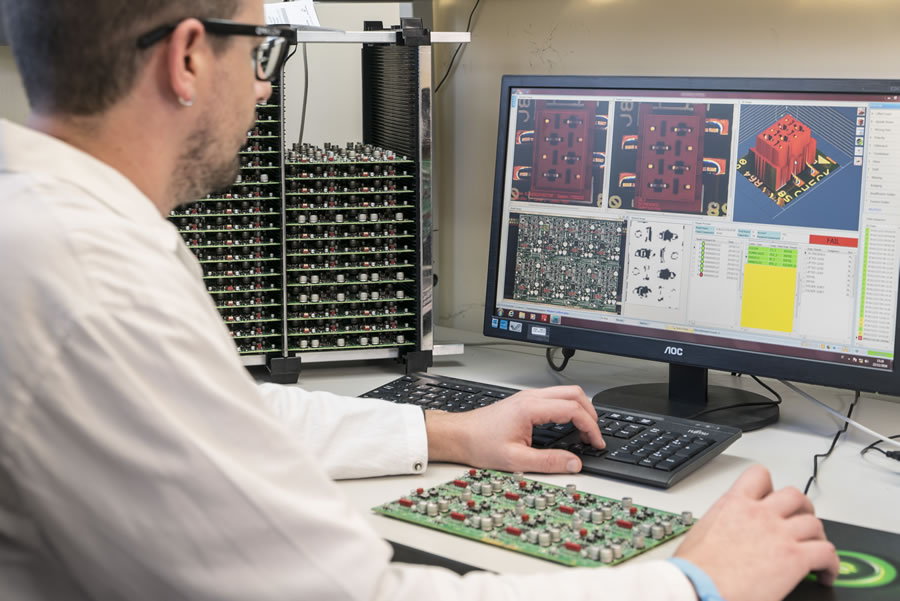

3D AUTOMATIC OPTICAL INSPECTION

Our high quality standard is achieved thanks to the AOI 3D control over 100% of the production.

SELECTIVE WAVE

On a daily basis, we certify the process of soldering and we record the thermal profiles of the boards we produce. The alloys utilized are periodically analyzed in our accredited laboratories.

SELECTIVE SOLDERING

Selective soldering carried out in an inert environment makes it possible

to automate the process and reduce the duration of production stages, thus enhancing quality.

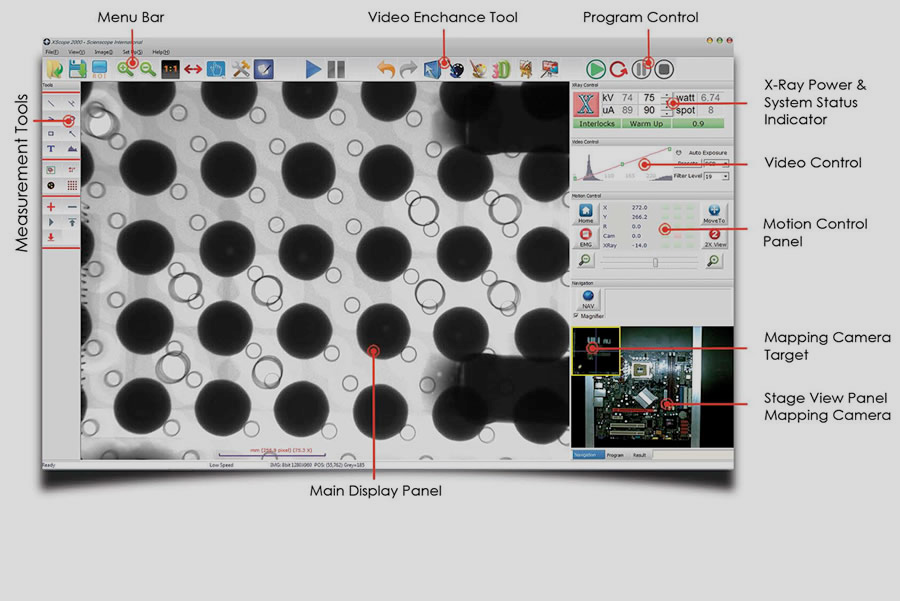

X-RAY INSPECTION

To complete the range of devices for the inspection of the sheets, we use x-rays, absolutely necessary for the validation of the production process and for service.

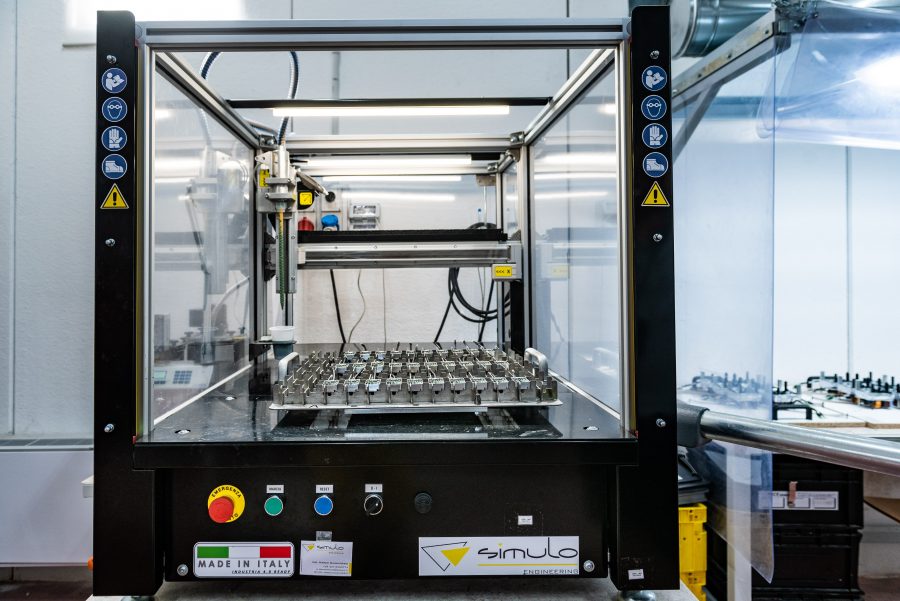

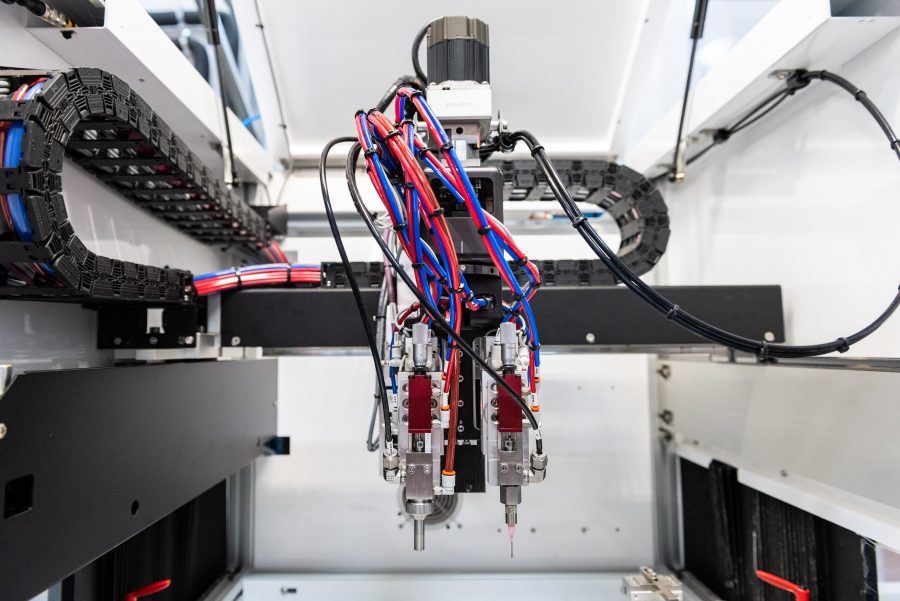

ICT WITH MOBILE PROBES

- n.4 mobile probes

- n.1 capacitive probe

- Check electrical continuity

- Parametric tests of components

- Check the frequency response of NETs

- Check the operation of digital circuits

- Speed of testing

- Generation of the test report including the serial number of the board

STAZIONE BGA REWORK

We offer repairs and the replacement of SMD components also for third parties.

BURN IN

Mce disposes of a climatic chamber to simulate the ageing of our electronic equipment. Thermal cycles can be customized within a range of temperature between -40 and 180 °C.

RESINATION

- Automatic dispenser managed by Cartesian robots

- Two-component, flexible, self-extinguishing polyurethane system.

CONFORMAL COATING

- Dispensing machine with automatic loading/unloading

- UV-sensitive paint